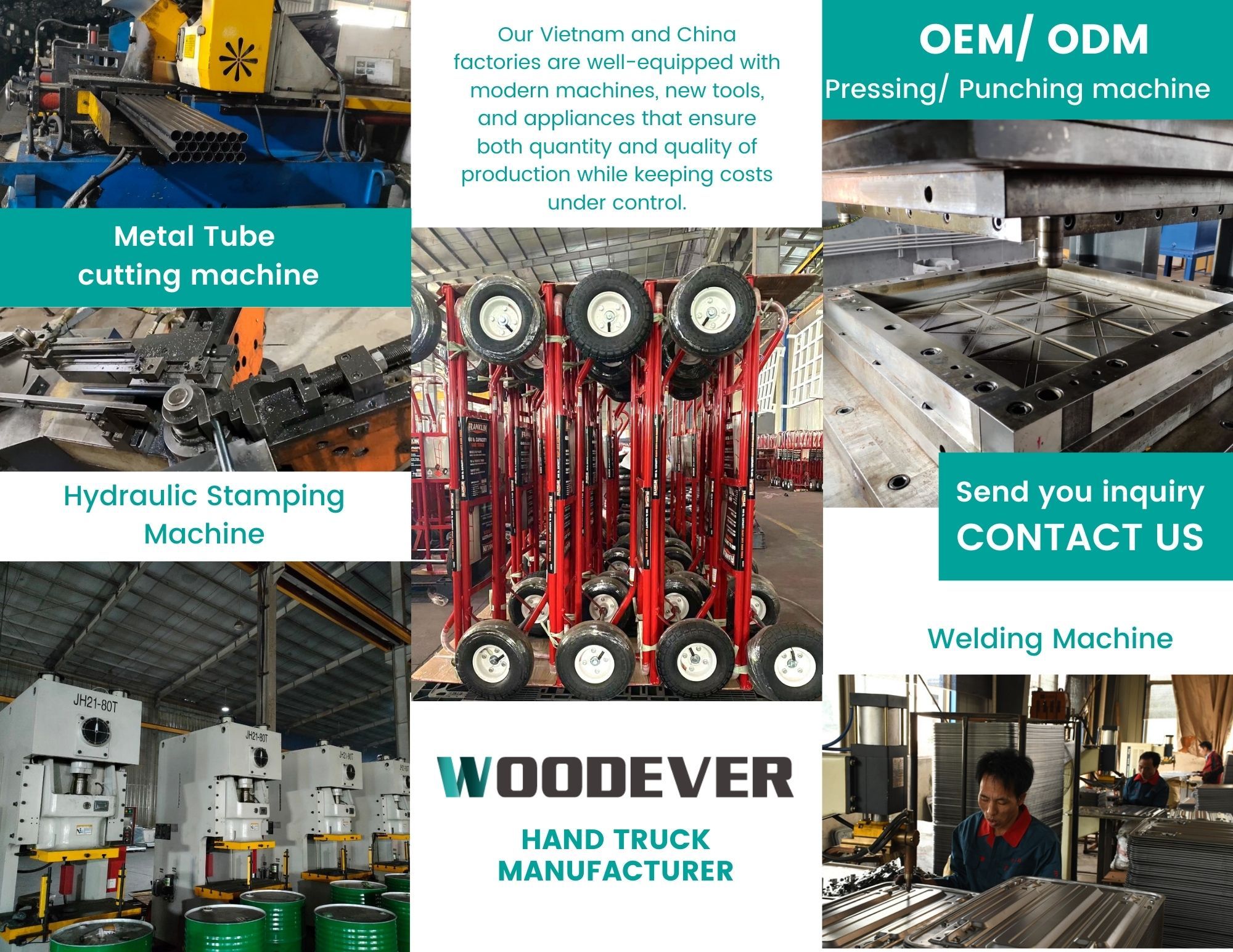

Production Facilities

What types of machines used in hand truck manufacturing process?

Hand truck manufacturing is a complex endeavor that necessitates hundreds of highly mechanical operations performed by heavy-duty machines to complete a single hand truck component. However, in the case of Engineered-to-Order (ETO) products, the complexity is multiplied by the engineering, costing, and change management that is frequently required. WOODEVER has a strong capacity to address that complexity. Our factories are fully equipped with metal and plastic fabrication machines for CNC plasma cutting, drill pressing, metalworking lathes, welding, hydraulic stamping, plastic injection, powder coating and more.

WOODEVER has a headquarter in Taichung city, Taiwan, and 2 manufacturing factories in China and Vietnam.

China Factory:

Established in 2008, the China factory is located in DongXi Industrial Zone, Jinhua City, Zhejiang Province, China. With a total area of over 30,000 meters square and 115 employees, our factory is capable of producing 45000 units monthly. Our factory is proud to be accredited BSCI certificate, which is a business-driven initiative for companies committed to improving working conditions in the global supply chain.

China Factory Production Facilities:

Powder Coating

Powder coating is a dry coating process that can be applied to any conductive metal that can withstand temperatures of up to 400°F. At this point, the hand truck's frame and nose plate will be coated, providing a protective layer that will last longer in humid and high salty air environments.

Metal Cutting Machine

When compared to spatter sparkles caused by hot cutting, the automatic circular sawing machine uses the cold cutting method for tube cutting, with the blade moving at a slow speed and sawing at a low temperature. The main advantage of cold cutting is that the cutting edge is smooth and burr-free, eliminating the need for a second deburring operation. Our cutting machine can cut multiple tubes at the same time, saving production time significantly.

Hydraulic Tube Bending Machine

In our factory, hydraulic bending machines are preferred over original CNC bending machines because they are better suited to metal frames with simple structures. The hydraulic bending machine's simple operation makes the manufacturing process very efficient. The hydraulic bending machine is made by cold bending, which eliminates the need for additional heat to complete the bend. The cold bend is more efficient than the hot bend, which requires cooling after the bend is completed.

Drill Press Machine

Compared with a benchtop metal drilling machine, a floor-type drilling machine has more power and high capacity, which is the best choice for processing large metal. The components processed on the drill machine will be fixed with specialized fixtures to stabilize the processed items, and avoid loosening and dislodging which may cause inaccurate hole position and inconsistent top and bottom problems. The parts that need to be screwed should be reserved for holes by the drilling machine.

Hydraulic Press Machine

Forging is the process of forming metal by pressure. The force of mechanical impact allows the metal material to be molded into the desired shape. In the manufacturing process, in order to make the material soften and easy to process, it is necessary to heat the raw material and then forge it. The metal products made by forging are resistant to high strength impact and greatly increase the load capacity.

Power Press Machine

Power Press Machine, also known as Stamping Machine or Punching Machine, is a semi-automatic metal fabrication machine. Pressing is a cold processing method that uses stamping equipment to shape flat metal into a specific shape, such as cutting, bending, or shaping into the shape and size of a mold. It is used for metal forming of thin materials, and its one-piece structure increases the durability of the finished product. Stamping machines are used to make the nose plates of hand trucks.

Vietnam Factory:

The high tariff rate in the trade war between USA and China has made Vietnamese suppliers more competitive than ever. In response to this international situation, WOODEVER has set up a new supply chain in Nam Tan Uyen Expanded Industrial Zone, Binh Duong Province, Vietnam with a total area of more than 45,000 meters square. The factory is equipped with automatic facilities for lean production, together with 230 employees and an experienced R&D team. It is highly potential to maximize production capacity up to more than 50,000 units of hand trucks monthly to meet the demand of the US and EU markets.

Vietnam Factory Production Facilities:

Heavy Duty Gap Bed Lathe

Easily selectable spindle speeds in geometric progression, the spindle speed is accurately controlled by gearbox rotation. It is fixed on the tool holder, and the metal pipe cutting and shaping can be done on the cart by using the tool machine for turning to process.

Hydraulic Stamping Machine

It is also known as hydraulic forging. It has suitable fluidity to improve the rotating efficiency and make the machine performance stable for long-term operation

Pipe Cutting Machine

For any kind of steel tubes (like mild steel, stainless steel, copper and aluminum...etc.) and different shapes (round, square, rectangular and oval...etc.). The machines are high efficiency, quick blade change, durable and low spare parts consumption semi-auto tube cutting machines.

Powder Coating Line

It is a fully automatic spraying machine that sprays powder coating on the hand truck's surface and cures it by baking it at high temperatures to form a protective layer.

Press Machine

It is a wide range of punching processes, also known as stamping, in which a metal plate is inserted into a mold and pressed into the mold to form a specific shape by descending and striking the press.

What we can do for you:

WOODEVER’s factories are well-equipped with modern machines, new tools, and appliances that ensure both quantity and quality of production while keeping costs under control. Please contact us if for any additional information.